Warehouses play an importance role in the supply chain, often overlooked by shippers and their partners. They serve as a crucial starting point for every logistics supply chain service, from goods storage at the origin to the transportation phase and finally to warehouses at the destination. Warehouse with accurate management information system is paramount, as it allows companies to track and manage their assets effectively, ensuring the accurate quantification of each item in their inventory, manage its production planning and scheduling system to meet commitment to end users.

The way new products are introduced and distributed has evolved significantly in the era of technology. Nowadays, new products are often introduced through live video streaming to both domestic and global audiences. Customers can place orders in real-time, and online payments are processed swiftly. The products are then efficiently processed and shipped from the nearest warehouse facility, reaching end consumers in just a matter of days. This rapid and efficient distribution process has reshaped the way businesses bring products to market.

The evolution of product distribution has impacted on manufacturing processes and its planning. Firstly, it has led to a significant reduction in the product life cycle, enabling products to reach the market more rapidly. Secondly, it has facilitated the production of smaller quantities, as products can be manufactured in response to real-time demand generated by system rather than relying on forecasts. Consequently, the requirement for large storage facilities has significantly diminished.

As a result, the demand for large storage facilities has been substantially reduced, necessitating a reconfiguration of business strategies. In the near future, shippers or manufacturers are considering the leasing of smaller warehouse facilities strategically located in close densely populated areas or mid-town location. This proximity allows shippers to store finished products that enables them to quickly and efficiently reach end consumers, effectively meeting their expectations for swift delivery. This adaptation to changing market dynamics underscores the significance of adaptability in the technology-driven supply chain landscape.

Many logistics and forwarder companies can take advantage of this opportunity by reconfiguring available space for warehousing. This can be especially beneficial for items that require specialized storage conditions such as temperature control or clean storage facilities, which can be integrated into the office environment. Registering as a transporter on Mahyu’s digital platform empowers companies to expand their service range to include integrated forwarding and warehouse services. This to allows them to be easily discoverable by both domestic and global users and conduct their integrated services in a real time platform.

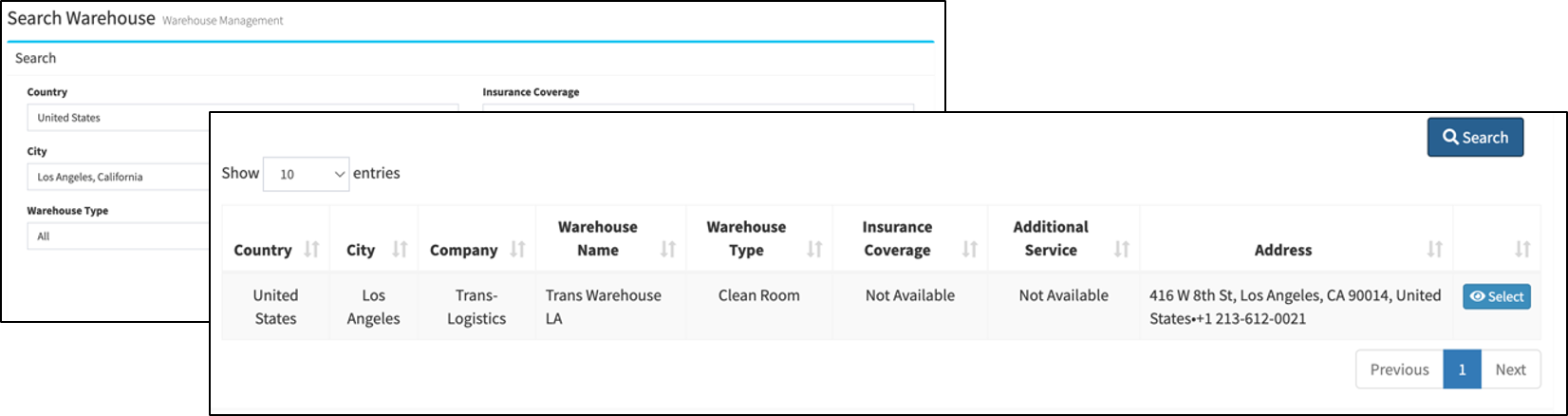

The Mahyu platform is designed to provide not only for transportation and ecommerce logistics, but to include warehouse operators. The warehouse feature offers various services: general area, cold storage, and dust-free room facilities to meet the diverse needs of customers. Shippers/consumers can easily search for warehouses based on their preferred type of specific city, country, or requirements warehouse service.

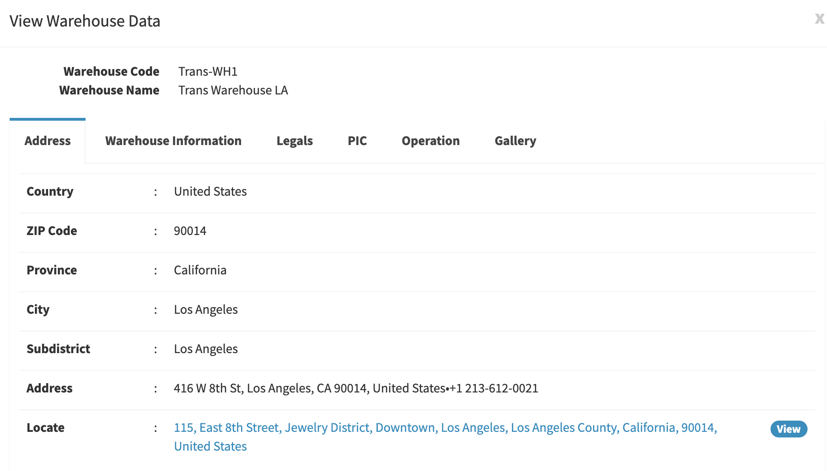

The system subsequently generates a comprehensive list of available warehouse operators in the search location, providing detailed features of each warehouse. This includes their operating hours, available equipment, surrounding environment, working hours, premises’ legal document, and precise location details. This enables shippers to carefully evaluate and select the preferred warehouse operator based on shipper specific needs that match operator’s qualifications.

Our platform algorithm is properly designed and developed to ensure that every aspect of shipper requirements aligns with the capabilities of the warehouse operator, minimizing any potential delays or mishandling. The platform also offers direct notifications to each warehouse location, keeping them informed of impending shipments or pickups.

This advanced notification system allows warehouse operators to efficiently prepare and stage goods in advance. Furthermore, when a driver is in close proximity to the warehouse, Mahyu automatically dispatches notifications to the warehouse personnel in charge, streamlining the transfer of shipments from the staging area to the loading area for efficient and timely handling.

The configured Mahyu warehouse management algorithm comprehensively monitors and tracks every movement of goods, both incoming and outgoing. It automatically records these movements and shares this data with the shipper. This functionality enables shippers to have real-time updates on the status of their internal inventory levels. This automatic adjustment of the accounting balance sheet ensures that shippers have accurate and up-to-date records of their inventory at all times. By utilizing streamlined platform, logistics and warehouse companies can optimize their operations, reducing delays, enhancing overall productivity while expanding their sales and marketing.